All manufacturers, EMS and OEM, can profit greatly from BOM Connector Enterprise

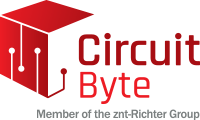

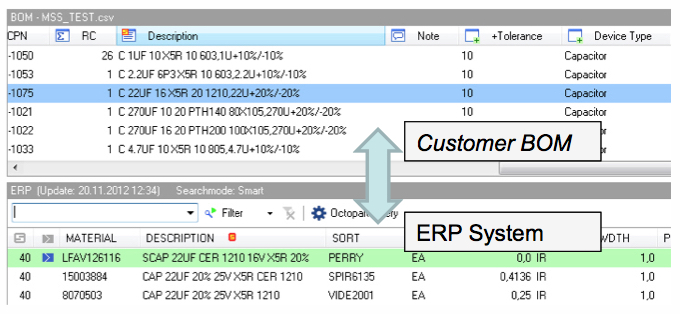

The graphic below shows how BOM Connector Enterprise works in a typical customer environment.

Customer data is pulled into the BOM Connector Enterprise database via direct connections to the key data sources. Most important of these is the ERP system. Additional sources of technical or commercial data, such as a CMS system or a PLM system can also be connected. And of course, PCB data or manufacturing process data can be brought in from an MES system. In short, wherever you have information that can be used to improve your BOM data and quotation process flow, BOM Connector Enterprise will interface to it.

As a result of this clean data flow, many different types of users within the company can take use BOM Connector Enterprise to improve their tasks. From design engineers who want to quickly check component technical properties and end-of-life information to help them choose the right part early in the cycle, to process and manufacturing engineers who need to get the BOM smoothly through to production. And of course, operative or strategic purchasers who need to wade through myriad offers in order to get the best price quickly.

And last but not least, certainly for EMS companies, a customer sends over raw BOM data – in varying formats, contents and quality – that needs to be imported, checked, “prepped” and processed, all under time pressure.

Our integrated tool is ideally designed to provide quick ROI to those who implement them.

BOM Connector Enterprise Modules

BC-LINK – The backbone of the entire system

Tie your ERP System tightly into the BOM scrubbing and cost calculation process

Features

- Loads all desired ERP material data into BOM Connector Enterprise for search, prep, compare and other tasks

- Direct ERP connection using existing, proven technology

- SQL statements, Oracle “Views”, OLEDB, ODBC – depending on your ERP system

- SAP Interface via RFC/BAPIs

- No extra ERP costs incurred

- Automatic, scheduled or triggered task

Examples of ERP Systems connected

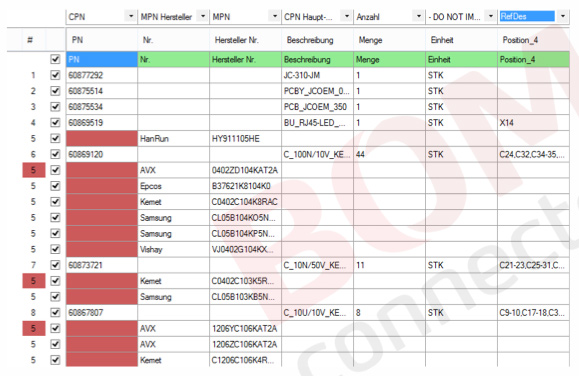

BC-READ – Read any BOM and write to a Standard Format

Read in even the most complex BOMs and create a standard “Golden BOM” in your company format. EMS companies can store customer profiles for maximum reusability

Standardise BOM output

- Read in wide variety of external BOM formats (.XLS, .CSV, .TXT etc.)

- Reader graphically recognizes patterns and variations

- Proper handling of manufacturer partnumbers (MPNs)

- Automatic generation of an internal code for BOMs without customer partnumbers (CPN)

- Export a standard desired format using easy-to-create templates

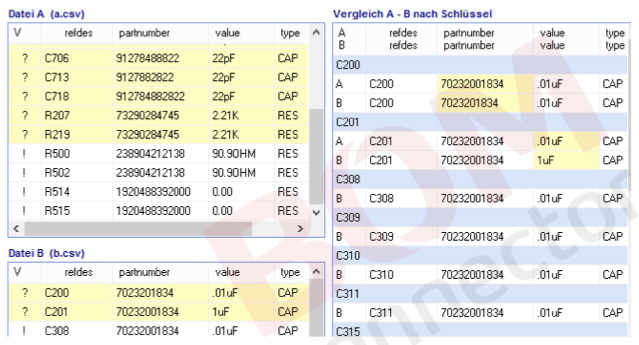

BC-CHECK – Content and Revision Compare

Check, control and correct BOM revisions

Features

- Check BOM for mistakes (qty mismatch, part mismatch, etc.)

- BOM / PCB Check

- BOM to BOM compare for revisions

- ERP – external BOM compare

- ERP – MSS compare and sync

BC-PREP – Preparing I Editing I Scrubbing BOMs

Create a golden BOM with advanced “scrubbing” features. Check for part availability in your ERP system with our patented “SmartSearch” technology

Features

- Clean up and enhance the information in the BOM

- Quick match parts in BOM and ERP parts based on partnumber, MPN or content

- “SmartSearch” intelligently compares description fields regardless of format or sequence

- Create and maintain new parts

- “ERP Viewer” feature allows easy exchange of component data between EMS supplier and customer

- All entries stored for future use

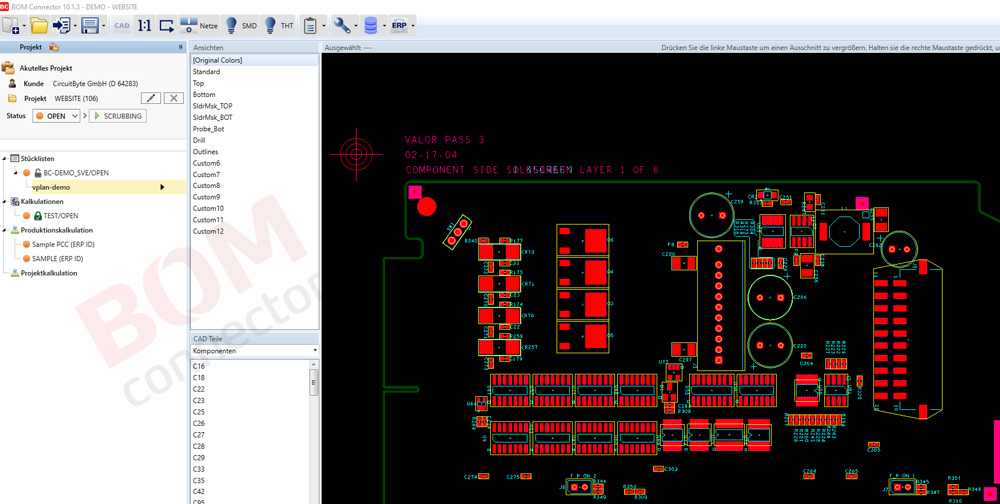

BC-CAD – Integrated Design Viewer

Read PCB data in virtually any format. Use for visualization or to enhance or check against the BOM and calculate manufacturing process costs

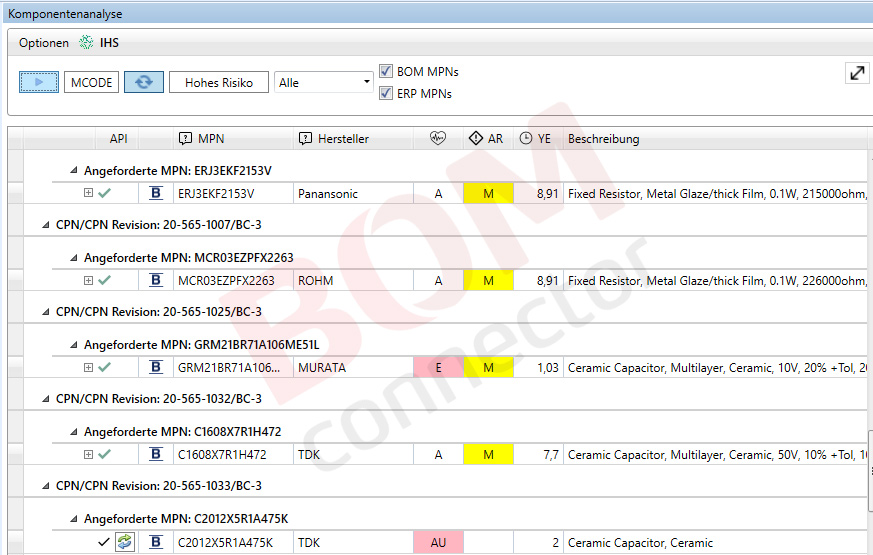

BC-COMPONENT ANALYZER – Get the most accurate, real-time information as possible

Combine advantage of two powerful market leaders in component data mining – IHS and Silicon Expert – to get quicker access to the information, transfer the information into the BOM with a simple mouse-click and search for alternatives if needed

BC-QUOTE – Faster and more accurate material cost calculation

Check part availability and calculate purchasing costs, overages, NRE costs and more

Dramatically shorten your quoting time with our growing number of collaborations and global network. Find the parts you need at the best possible price and improve connectivity to your supply chain. Fast and intuitive!

Use our innovative real-time DistiDirect™ feature to access our global network of component suppliers and manufacturers to easily, quickly and fully calculate the cost for your quoting.

- Drastically reduce quoting times

- Get prices from ERP system, distributors or manual entry

- Color-coded displays helps you sort multiple search results

- Purchase quantities and bulk pricing calculated based on production quantities

- Check for MPN or SKUs

- Send out distributor RFQs per mouse-click

- Link distributor quotes and price lists

- Distributor status maintenance – preferred, “black list” etc.

- „Best Price” function from any source

- Support for consignment parts and multiple currencies

- Save prices independent of customer for quick requoting

- Save quotes and prices in BC QUOTE Database. No more repeat checking!

DistiDirect checks online with a variety of distributors such as: Arrow Electronics, Inc, Avnet Group: Abacus, EBV, Silica and United, Avnet, Digi-Key Electronics, Weltron, Blume Elektronik, Farnell, Future Electronics, Mouser Electronics, Inc, MyArrow, Octopart, RS Components GmbH, Rutronik, Schukat, Sourcengine Texas Instruments, Elfaro, GUDECO, AL-Elektronik and EVE using your company login.

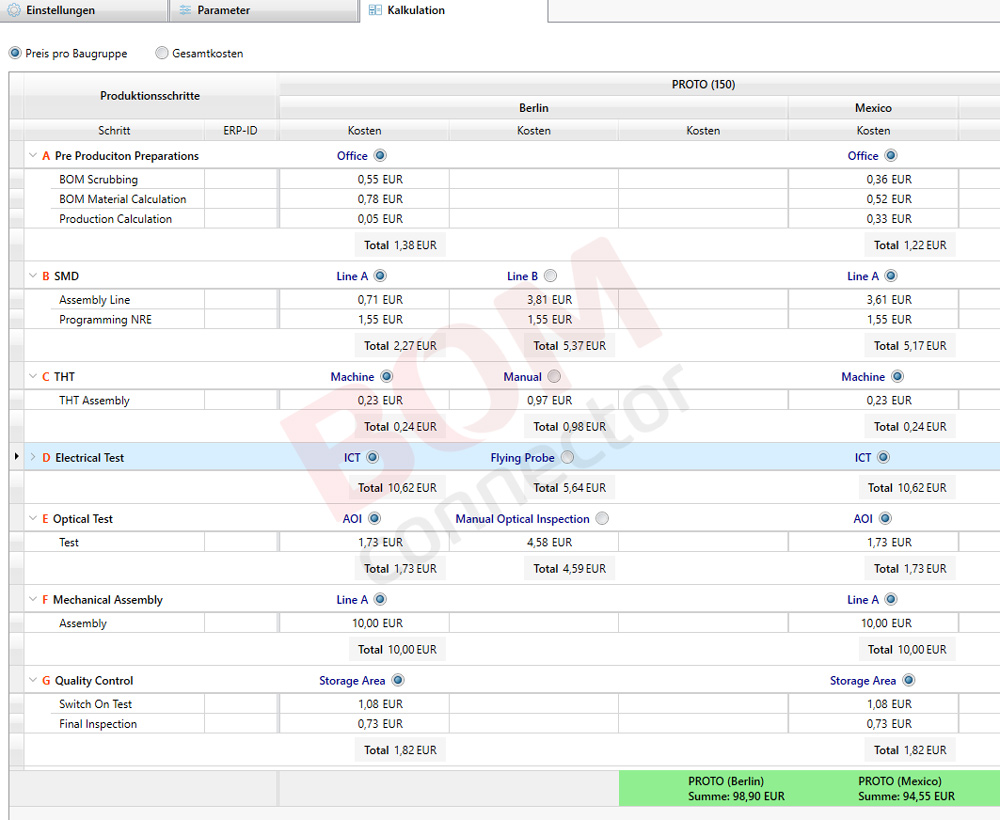

BC-QUOTE – Production Cost Calculation

Faster and More Accurate

Features

- In addition to material costs

- Calculate SMT, THT and hand mounted components and solder joints

- Process costs such as stencil and fixture

- Direct link to your MES system

- DFM cost analysis based on quality of the layout

- Finally – a complete cost estimate based on all factors

- Vendor information taken from ERP or external sources such as Octopart

- Supplier information can also be handled directly within BOM Connector

- Import customer AML files

- AML compare between ERP and customer

- Preferred, alternative and blocked part and/or supplier support